Prior to the Industrial Revolution, coins were produced differently. There were individualized minting shops, each led by a “mint master.” The process was rarely federalized. Local mints made coins specifically for their regional areas. These coins were then authorized by an authority figure to make sure that they were of the right weight, purity of metal, and design.

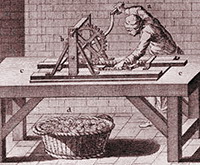

Coining by screw press (since about 1550)

During historical periods, the dies used to mint the coins were each hand made by an artisan know as an engraver. The negative face was carved into a metalworker’s anvil, and the tails side of the coin was carved into a hammer. The blank was then made by hand and placed, while warm, onto the anvil with a tool so that the worker was not burned. A worker would use the hammer to strike the coin, impressing the required designs onto each side. Because of this you will sometimes see old coins off center or not symmetrically made.

Hand operated rolling mill, for putting the edge impression on to coins

Little changed in medieval Europe; however, monies during this time became very thin. The blanks used in this period were hand cut from metal sheets. After cutting they were weighed, and extra weight was removed.